Uses

For exhausting hot gasses, paint fumes (excluding, cellulose), steam, smoke and dust laden air, available in diameters 250-1250mm.

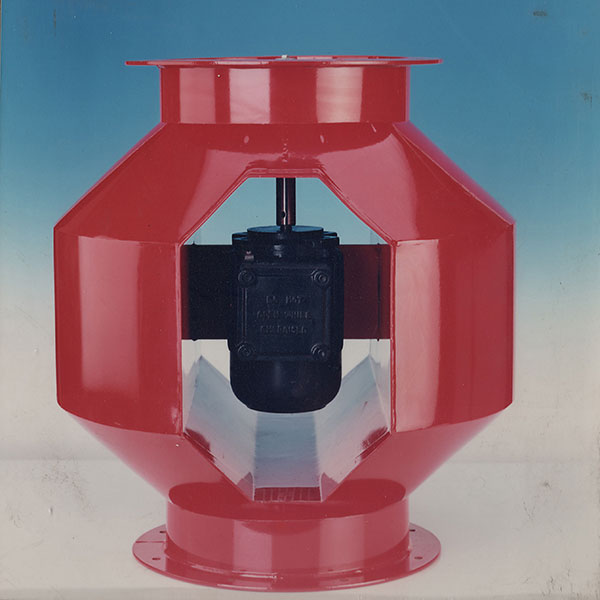

Fan Type NT

Normal Temperature – upto 80°C (176°F). Constructed in mild steel with a polypropylene impeller and Class F insulation motor. Special corrosion- resistant finishes available. Standard finish - Galvanised.

Fan Type HT

High Temperature - upto 200°C (392°F). Constructed in mild steel with an aluminium impeller and Class F insulation motor. Special corrosion- resistant finishes available. Standard finish - galvanised.

Motors

Standard three or single phase motors can be fitted along with ATEX ZONE 1 or 2 and company specification units when required.

Plastic Fans

This range of fans can also be constructed from rigid PVC sheet reinforced with fibreglass and suitable for a wide fans of uses in the chemical industry and in the extraction of acid fumes from industrial processes. Dimensions and performance data as for normal Bifurcated fans.

For exhausting hot gasses, chemical vapours, steam and moisture laden air, available in diameters 250-1000mm. Max temp 60°C

Stainless Steel Fan Type 304

Ideal for use in the catering industry for air temperature upto 80°C (176°F). For exhausting warm air and steam. Constructed throughout in stainless steel with a polypropylene impeller and Class ‘F’ standard motor with a stainless steel extended shaft.

Stainless Steel Fan Type 316

Uses mainly in the chemical and allied trades. Suitable for most acid vapours upto 80°C (176°F). Constructed throughout in stainless steel with a polypropylene impeller and Class F standard motor with a stainless steel extended shaft.

Extra Features Available

- Mounting feet

- flexible connections

- AV Mountings

- Mating Flanges

- Inlet Cones

- Guards

- Back-draught shutters

- Special Paint finishes

Finish

- Standard Fans: Galvanised

- Optional Finishes: Epoxy Resin, Metal Spraying