Applications

Engineers must consider the use of Centrifugal Fans instead of Axial fans for some of the following reasons:

- High Temperature

- Low Noise Levels

- Dust & Fume Extract

- High Static Watergauge

Types of Centrifugal Fans

There are different types of Centrifugal Fans covering air volumes from 85 to 100,000m³/hr and from 25 to 15,000 PA. Each application requires a fan with different characteristics, whether it be the blade design, the width of the casing or even the method of drive. By way of a guide as to which is the best fan for certain projects, we list below information that might assist the potential user.

Paddle Blade Fans

This type of fan is used for the conveying of dust, wood and paper refuse, cotton fly etc. Since the blade design prevents ‘build up’ of waste materials, discharge velocities vary dependent upon what is being conveyed in the air stream. Normally in the region of 7-20 mtrs/sec.

Multivane or Forward Curved Fans

Used for general ventilation purposes – not good for dust etc. Limited pressure characteristics. Normal discharge velocities 5-13 mts/sec

Backward Curved or Backward Sloping Fans

Non overloading power characteristics suitable for very light dust applications (eg clean side of dust collector) where a good efficiency is required. Used for high pressure ventilation systems or where the system resistance could fluctuate. Normal velocities 9-16 mts/sec

Aerofoil Fans

The most efficient of all centrifugals fans, ideally suited to general ventilation projects where there is no possibility of dust contamination. Recommend for high pressure ventilation systems or where the system resistance could fluctuate. Normal discharge velocities 7-15 mts/sec.

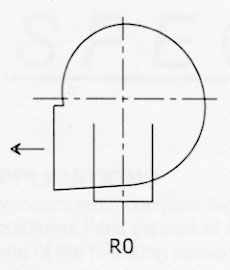

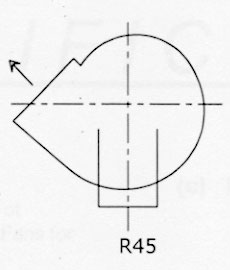

High Pressure Blowers

As their name suggests, these fans are applied where the requirement is for high velocities, eg Air Curtains, refuse conveying etc Normal discharge velocities 15-30 mts/sec.